How to Prepare a SWOT for a Manufacturing Company

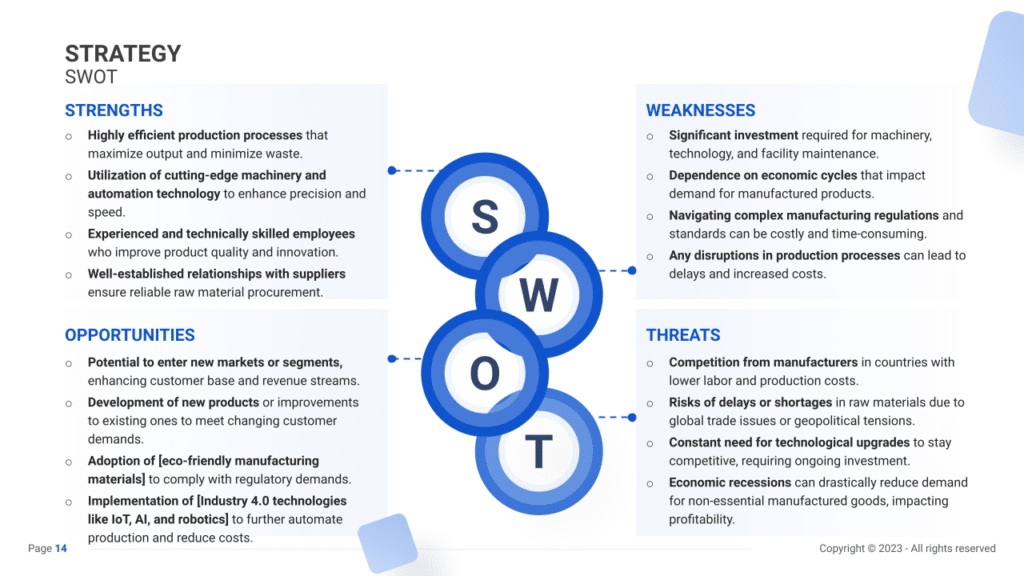

A SWOT analysis is crucial for a manufacturing company’s business plan. SWOT, standing for Strengths, Weaknesses, Opportunities, and Threats, offers a comprehensive view of the business. Strengths and weaknesses are internal, controllable aspects, while opportunities and threats are external market factors.

In a manufacturing context, a SWOT analysis reveals the company’s position in the industry and highlights areas for growth and improvement. Strengths might include advanced technology, skilled labor, or efficient production processes. Weaknesses could be outdated equipment or high production costs.

This article will explore various examples of strengths and weaknesses, guiding manufacturing companies in integrating these insights into their business strategies.

Strengths

Empower your Manufacturing business with inherent strengths that drive efficiency, quality, and market prominence.

- Advanced Technology Infrastructure: Cutting-edge machinery and technology streamline production processes, ensuring precision and enhancing productivity.

- Example: Invest in Industry 4.0 technologies, such as IoT and automation, to optimize manufacturing processes and reduce operational costs.

- Skilled Workforce: A highly skilled and trained workforce contributes to efficient operations, high-quality outputs, and adaptability to evolving industry demands.

- Example: Implement ongoing training programs to upskill employees, ensuring they stay abreast of technological advancements and industry best practices.

- Strong Supply Chain Management: An efficient supply chain minimizes disruptions, reduces lead times, and enhances the overall agility of manufacturing operations.

- Example: Foster strong relationships with reliable suppliers, implement inventory management systems, and explore just-in-time manufacturing practices.

- Established Brand Reputation: A well-established brand reputation signifies reliability, quality, and trust, contributing to customer loyalty and competitive advantage.

- Example: Leverage positive customer testimonials, industry certifications, and awards to reinforce the company’s reputation in marketing materials.

Weaknesses

Address weaknesses to fortify your Manufacturing business for enduring success and sustained growth.

- Dependence on Single Suppliers: Over-reliance on a single supplier may pose risks; diversify the supplier base to mitigate potential disruptions.

- Example: Identify alternative suppliers for critical components, ensuring a consistent supply chain even if one source faces challenges.

- High Energy Consumption: Excessive energy consumption may impact operational costs and environmental sustainability; implement energy-efficient practices and technologies.

- Example: Invest in energy-efficient machinery, implement energy-saving protocols, and explore renewable energy sources to reduce the overall carbon footprint.

- Product Complexity Challenges: Overly complex products may pose challenges in production efficiency and customer understanding; streamline product offerings where necessary.

- Example: Conduct a product portfolio analysis, identifying and optimizing products with low demand or high production complexity.

- Limited Innovation Culture: A lack of a robust innovation culture may hinder competitiveness; foster a culture that encourages continuous improvement and creativity.

- Example: Establish innovation teams, encourage employee suggestions, and invest in research and development to drive product and process innovation.

Opportunities

Explore opportunities to elevate and expand your Manufacturing business in a dynamic market.

- Global Market Expansion: Leveraging global markets opens new avenues for growth; conduct market research and establish international partnerships.

- Example: Explore trade agreements, attend international trade shows, and customize products to meet the unique demands of diverse markets.

- Sustainable Practices and Products: Embracing sustainability aligns with market trends; integrate eco-friendly practices and develop sustainable product lines.

- Example: Implement recycling programs, source sustainable materials, and promote eco-friendly product features to attract environmentally conscious consumers.

- Customization Trends: Rising demand for customized products presents an opportunity; invest in flexible manufacturing processes to accommodate personalized requirements.

- Example: Develop an online platform for customers to customize products, allowing them to choose specifications and features.

- Collaboration with Technology Providers: Partnering with technology providers enhances manufacturing capabilities; explore collaborations for augmented reality, data analytics, and smart manufacturing.

- Example: Collaborate with tech companies to integrate smart manufacturing solutions, enhancing efficiency and providing data-driven insights.

Threats

Anticipate and navigate potential threats to ensure the resilience of your Manufacturing business.

- Supply Chain Disruptions: Global events or economic uncertainties may disrupt the supply chain; diversify suppliers and implement risk mitigation strategies.

- Example: Maintain strategic stockpiles, develop contingency plans, and monitor geopolitical factors to proactively address potential disruptions.

- Rapid Technological Changes: Fast-paced technological advancements may render equipment obsolete; invest in future-proof technologies and continuous workforce training.

- Example: Establish technology roadmaps, conduct regular equipment assessments, and allocate budget for timely upgrades to stay competitive.

- Intense Competition: A competitive market may impact pricing and market share; focus on differentiation strategies, quality, and customer service.

- Example: Conduct competitor analyses, differentiate through unique features or services, and implement pricing strategies that reflect the value offered.

- Regulatory Compliance Challenges: Evolving regulations may impact manufacturing processes; stay informed and ensure compliance through proactive adjustments.

- Example: Establish a regulatory affairs team, conduct regular audits, and implement training programs to ensure adherence to changing compliance standards.